In the world of material handling and automated systems, "Telescopic Guide Rails" play a crucial role in ensuring smooth operations and efficiency. According to industry expert Dr. Emily Chen, a prominent figure in the field of automated logistics, "The integration of telescopic guide rails into conveyor systems not only enhances stability but also maximizes flexibility in space utilization." Understanding the nuances of these essential components is vital for professionals looking to optimize their operational workflow.

When considering the purchase of Telescopic Guide Rails, it's important to explore both their functionality and benefits. These rails offer adaptable options that can extend and retract, catering to varying loads and minimizing unnecessary space requirements. Furthermore, the right selection can significantly influence the safety and performance of your systems. Therefore, navigating the market for these rails can be a daunting task without the proper guidance and insights.

In this ultimate guide, we will delve into the critical aspects to consider before making a purchase. From material choices and load capacities to installation methods and maintenance, our aim is to equip you with the knowledge needed to make informed decisions. Whether you're upgrading existing systems or implementing new automation solutions, understanding the fundamentals of Telescopic Guide Rails is the key to achieving operational excellence.

Telescopic guide rails are essential components in various industrial applications, providing a reliable mechanism for linear motion and accessibility. These rails are designed to extend and retract smoothly, enabling efficient movement for equipment and machinery. Their unique construction allows for compact storage without sacrificing stability or load-bearing capacity.

According to a report by Grand View Research, the global telescopic rail market is expected to reach USD 2.6 billion by 2027, with a compound annual growth rate (CAGR) of 5.5%. This growth highlights their increasing importance across diverse sectors.

Common applications of telescopic guide rails can be found in the automotive, aerospace, and manufacturing industries. In automotive assembly lines, for instance, these rails facilitate the movement of heavy machinery and tools, optimizing workflow and productivity. Similarly, in the aerospace sector, telescopic rails are crucial in handling sensitive components during assembly, ensuring precision and safety.

A study conducted by MarketsandMarkets projects that the manufacturing segment will see substantial investment in automation, which inherently drives the demand for advanced guiding systems like telescopic rails. As manufacturing processes evolve, the versatility and efficiency of telescopic guide rails will continue to play a pivotal role in enhancing operational capabilities.

When choosing telescopic guide rails, several key features should be taken into account to ensure optimal performance and durability. First and foremost, consider the material of the rails. Common options include aluminum and stainless steel, each offering distinct advantages in terms of weight, strength, and corrosion resistance. Aluminum is typically lighter and easier to handle, making it suitable for applications where weight reduction is critical. In contrast, stainless steel provides additional strength and durability, ideal for heavy-duty applications or environments prone to moisture and chemicals.

Another important feature to evaluate is the load capacity of the guide rails. Different applications require specific load limits, so it's vital to choose rails that can handle your intended usage without risk of failure. Additionally, look for rails with smooth operation and minimal friction. This impacts not only ease of use but also the longevity of the product since reduced wear can significantly prolong the life of both the rails and the sliding components. Finally, ensure that the installation options are compatible with your system, as this can affect both performance and safety during operation.

| Feature | Description | Importance | Typical Range |

|---|---|---|---|

| Load Capacity | The maximum weight the rails can support. | High | 50kg - 200kg |

| Material | The composition of the guide rails affects durability and performance. | Medium | Aluminum, Stainless Steel |

| Length Options | Available lengths to fit different applications. | High | 500mm - 2000mm |

| Ease of Installation | How straightforward it is to install the guide rails. | High | Varies by design |

| Adjustability | Whether the rails can be adjusted for different needs. | Medium | Fixed or Adjustable |

| Price Range | The cost associated with purchasing the guide rails. | High | $50 - $500 |

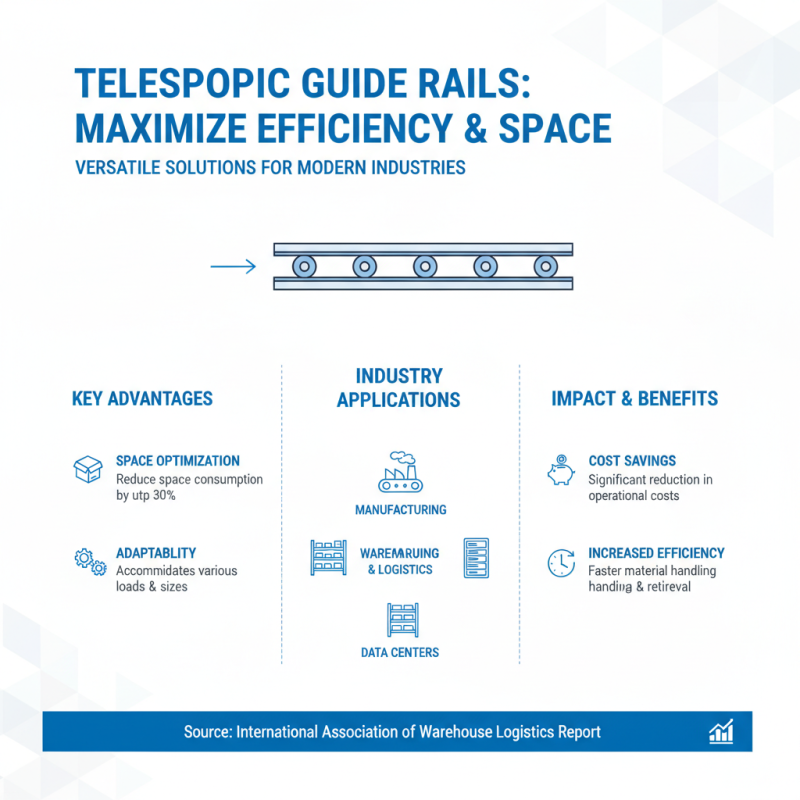

Telescopic guide rails have become increasingly popular across various industries due to their versatility and efficiency. One of the main advantages of using telescopic guide rails is their ability to maximize space utilization, allowing for more efficient storage and retrieval of materials. According to a report by the International Association of Warehouse Logistics, companies that utilize these guide rails can reduce space consumption by up to 30%, leading to significant cost savings. Additionally, their adjustable nature means that they can accommodate various loads and sizes, enhancing adaptability in manufacturing and storage environments.

Another compelling benefit is the enhancement of safety in industrial settings. Telescopic guide rails often come equipped with features that minimize the risk of accidents during material handling. The Occupational Safety and Health Administration (OSHA) states that implementing proper guide rail systems can reduce workplace injuries by up to 25%. This reduction not only protects employees but also minimizes operational downtime, making businesses more efficient overall.

Tips: When considering telescopic guide rails, always assess the specific needs of your operation. Evaluate load capacities and ensure that the materials used in the guide rails are suited for your environment. Regular maintenance and inspections can also extend the lifespan of your guide rails, further maximizing your investment. Additionally, working with a knowledgeable supplier can help you choose the best options that align with your operational goals.

When considering the installation of telescopic guide rails, understanding optimal practices is crucial to achieving both functionality and safety. According to the International Organization for Standardization (ISO), proper installation can increase the longevity of guide rails by up to 30%, reducing maintenance costs significantly. Proper alignment, ensuring level surfaces, and adequate support can prevent unnecessary wear and tear, thereby enhancing operational efficiency.

Tips: When installing telescopic guide rails, always start by assessing the installation environment. Ensure that the surface is clean and free of obstructions, as debris can interfere with the smooth functioning of the rails. Additionally, use a spirit level to guarantee that all components are horizontally aligned; this helps maintain load distribution evenly across the rail system.

Furthermore, selecting the right materials for the application is essential. A recent report from the American National Standards Institute (ANSI) highlights that the choice of high-quality materials can improve the load capacity of guide rails by nearly 25% compared to lower-grade alternatives. When installing telescopic guide rails, always refer to manufacturer guidelines for torque specifications to ensure secure fittings. Adhering to these best practices not only enhances performance but also ensures safety during operation.

When it comes to telescopic guide rails, proper maintenance and care are essential for ensuring their longevity and functionality. Regular inspections should be scheduled to check for signs of wear and tear, such as rust, bending, or misalignment. Keeping the rails clean is equally important; debris and dirt can accumulate, leading to rust formation and decreased performance. Using a gentle cleanser followed by a thorough drying process helps prevent corrosion and maintains the smooth operation of the guide rails.

Lubrication is another critical aspect of care for telescopic guide rails. Applying the appropriate lubricant to the moving components not only reduces friction but also minimizes wear on the surfaces. It is advisable to follow the manufacturer's guidelines regarding the type of lubricant to use, as this can significantly extend the life of the rails. Additionally, any loose screws or bolts should be tightened, and parts that show signs of degradation should be replaced promptly to avoid further damage. By adhering to these maintenance practices, users can ensure their telescopic guide rails remain effective and reliable for years to come.