In the realm of modern cabinetry, the importance of high-quality drawer glides cannot be overstated. Industry expert Martin Caldwell, renowned for his insights on functional furniture design, once stated, “The right drawer glides can transform everyday experiences into moments of effortless convenience.” This sentiment rings particularly true when discussing the innovative technology behind Drawer Glides Soft Close, which has gained traction among both homeowners and designers alike.

The incorporation of soft close mechanisms not only enhances the usability of drawers but also alleviates the concerns of slamming and noise, making it a pivotal feature in contemporary kitchen and living spaces. As we delve into the top 10 Drawer Glides with Soft Close mechanisms, we celebrate the seamless fusion of functionality and design. Each product highlights the remarkable advancements in drawer glide technology, ensuring that users enjoy a quiet and smooth closure every time. In a world where convenience and aesthetics are paramount, the significance of choosing the right drawer glides is clearer than ever.

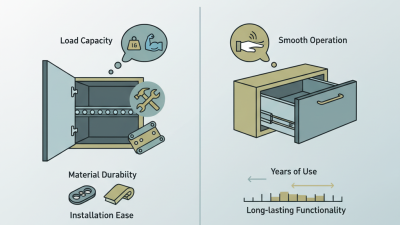

When selecting drawer glides with soft close mechanisms, several features significantly enhance their functionality and usability. Firstly, the smooth operation is paramount. Quality soft close mechanisms are designed to ensure that drawers close gently and silently, preventing slamming and making them ideal for family environments. This feature not only improves comfort but also protects the contents of the drawer from being damaged.

Another critical aspect to consider is the ease of installation and adjustment. Many modern drawer glides come equipped with user-friendly mounting systems, allowing for straightforward setup even for those with minimal DIY experience. Additionally, adjustable options can accommodate various drawer sizes and depths, making them versatile for different furniture styles. Stability and durability are also essential; high-quality materials ensure that the glides withstand daily use and maintain their performance over time, further enhancing their appeal for both residential and commercial applications. These features collectively contribute to a seamless and enjoyable experience when using drawers in any setting.

Soft close technology has revolutionized the way we interact with kitchen and bathroom cabinets, offering a seamless blend of functionality and elegance. This innovative mechanism ensures that cabinet doors and drawers close gently and silently, preventing the jarring noise typically associated with traditional hardware. The impact of soft close systems extends beyond mere convenience; it also enhances the overall ambiance of these essential spaces, contributing to a more refined and tranquil environment.

In kitchen settings, soft close mechanisms provide a practical solution to the daily hustle and bustle of meal prep and family gatherings. They eliminate the risk of slamming doors, which can be particularly important in households with young children or active family members. In bathrooms, where peace and serenity are often paramount, soft close cabinets help maintain a calm atmosphere, allowing for a more enjoyable experience during daily routines. With such benefits, it’s clear that soft close technology is not just an added feature; it is an essential aspect of modern cabinet design that significantly enhances user experience in both kitchens and bathrooms.

When selecting drawer glides with soft close mechanisms, the choice of materials plays a crucial role in their performance and durability. Common materials used in the construction of drawer glides include metal, plastic, and composite materials. Metal glides, often made from steel or aluminum, are known for their strength and longevity. They can support heavier loads and resist warping over time, making them an excellent choice for frequently used drawers. However, their weight can sometimes lead to a more complex installation process.

On the other hand, plastic glides offer a lightweight alternative that can be easier to install and maintain. They are resistant to corrosion and can handle moisture-rich environments, making them suitable for kitchens or bathrooms. However, they may not support the same weight capacity as metal options, and can be more prone to wear and tear under heavy use. Composite materials combine the benefits of both metal and plastic, providing a balanced solution that leverages the sturdiness of metal while keeping the installation process manageable. Understanding these material differences is essential in choosing the right drawer glides that meet the specific needs of functionality and aesthetic preferences.

When it comes to drawer glide performance, industry standards play a crucial role in ensuring safety, durability, and user satisfaction. The American National Standards Institute (ANSI) and the Kitchen Cabinet Manufacturers Association (KCMA) set forth guidelines that define acceptable levels of performance for hardware like drawer glides. According to the KCMA standards, drawer glides must be tested to withstand a load of at least 75 pounds to ensure they can handle daily use without compromising their structural integrity. This rigorous testing is essential for both residential and commercial cabinetry applications.

Moreover, the incorporation of soft close mechanisms in drawer glides is becoming a standard feature driven by consumer demand for enhanced usability. Reports indicate that soft close technology not only improves the overall user experience by reducing noise but also extends the lifespan of the drawer mechanism. In a study by the National Kitchen and Bath Association (NKBA), it was found that over 65% of homeowners prefer soft close drawer systems for their ability to minimize damage from slamming. This trend underscores the importance of adhering to established standards that promote functionality while enhancing the longevity and appeal of kitchen and furniture designs.

| Model | Load Capacity (lbs) | Material | Soft Close Mechanism | Compliances |

|---|---|---|---|---|

| Model A | 75 | Steel | Yes | ISO 9001 |

| Model B | 100 | Aluminum | Yes | BIFMA |

| Model C | 50 | Plastic | Yes | ANSI |

| Model D | 120 | Wood | Yes | CE Mark |

| Model E | 80 | Steel | Yes | RoHS |

| Model F | 90 | Aluminum | Yes | FSC |

| Model G | 70 | Wood | Yes | ISO 14001 |

| Model H | 85 | Plastic | Yes | ETL Listed |

| Model I | 95 | Steel | Yes | UL Certified |

| Model J | 110 | Aluminum | Yes | GreenGuard |

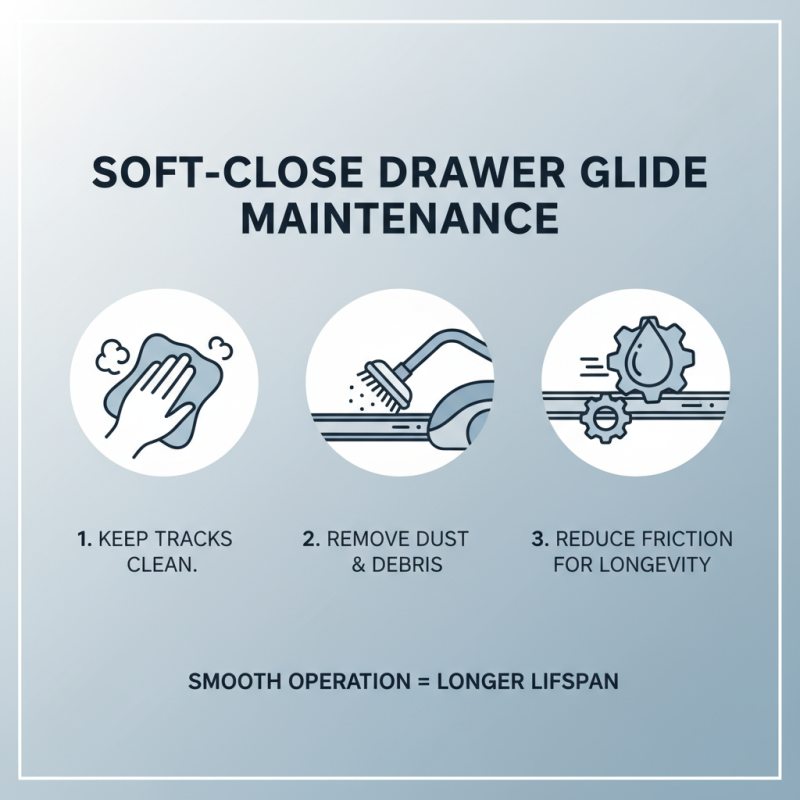

Maintaining soft close drawer glides is essential for ensuring their longevity and optimal performance. Regular maintenance helps prevent wear and tear that can lead to malfunctioning drawers. One of the simplest yet most effective maintenance tips is to keep the tracks and glides free from dust and debris. Use a soft cloth or a vacuum with a brush attachment to gently remove any buildup. This not only helps in smooth operation but also reduces friction, which can wear down the components over time.

Another important aspect of maintenance is lubrication. Applying a silicone-based lubricant to the glide mechanism and tracks can help enhance movement and reduce noise. It’s advisable to do this every few months, particularly in high-usage drawers. Make sure to avoid oil-based lubricants as they can attract more dirt and grime, leading to more frequent maintenance needs. Furthermore, periodically check for any loose screws or components and tighten them to prevent misalignment that could cause your drawers to stick or become difficult to open and close.

Lastly, be mindful of the weight limits of your drawer glides. Overloading the drawers can cause the soft-close mechanisms to fail prematurely. Reorganize contents to distribute weight evenly and ensure that nothing heavy is placed on top of the drawers, which could strain the glides. Following these simple maintenance tips will help you enjoy the effortless functionality of your soft close drawer glides for years to come.