Telescopic Guide Rails have emerged as essential components in a variety of modern applications, particularly in industries that demand efficiency and precision. These innovative systems enable smooth and controlled movement of loads, facilitating streamlined operations in both industrial and commercial settings. By leveraging the unique design of telescopic mechanisms, these guide rails can extend and retract to accommodate varying loads and spatial constraints, making them invaluable in environments like warehouses, manufacturing plants, and automotive assembly lines.

The functionality of Telescopic Guide Rails is rooted in their ability to provide a stable and adjustable pathway for moving objects. This adaptability not only enhances safety but also improves productivity by allowing for quicker access to stored items or equipment. As industries continue to evolve and the demand for versatile solutions grows, understanding the principles and applications of telescopic guide rails becomes increasingly important. This introduction serves as a prelude to exploring their intricate design, various uses, and the transformative impact they have on modern operational efficiency.

Telescopic guide rails are an essential component in many modern machinery and equipment, designed to facilitate smooth linear motion while maximizing space efficiency. These rails consist of multiple sections that slide into one another, allowing them to extend and retract seamlessly. This design not only reduces the overall footprint of devices but also provides superior stability and precision during operation. The sliding mechanism typically relies on high-quality bearings and lubrication systems, ensuring frictionless movement and prolonged service life.

In various applications, telescopic guide rails can be found in automated systems, modular storage solutions, and even in the medical field, where precise adjustments are crucial. Their ability to support significant loads while minimizing vibrations makes them ideal for manufacturing equipment, conveyor systems, and robotic arms. Moreover, they can be easily integrated into existing designs, providing versatility across industries. By improving operational efficiency and enabling compact designs, telescopic guide rails play a vital role in advancing modern engineering solutions.

Telescopic guide rails are innovative mechanical systems designed to provide smooth linear movement across various applications. These rails operate on a simple yet effective mechanism that involves multiple sliding segments, which extend and retract like a telescope. When force is applied, the segments glide over one another, allowing for extended reach and ease of movement. This design not only enhances stability but also minimizes wear and tear, making them suitable for high-frequency use in dynamic environments.

In different settings, telescopic guide rails adapt to a variety of functional requirements. For instance, in industrial automation, they support the precise movement of machinery and tools, facilitating efficient production lines. In the realm of storage solutions, their ability to compress into a compact space enables optimal use of limited areas while still allowing for easy access. Furthermore, in automotive applications, these rails assist in various mechanisms, from sliding doors to adjustable seats, illustrating their versatility across sectors. As a result, the mechanism behind telescopic guide rails showcases their ability to enhance operational efficiency and user convenience in modern applications.

Telescopic guide rails have become essential in modern manufacturing industries, offering efficient solutions for smooth and controlled linear movements. These guide rails are designed to extend and retract seamlessly, providing stability and precision during various manufacturing processes. According to a recent market analysis report, the global telescopic rail market is projected to grow at a CAGR of 6.4% over the next five years, highlighting their increasing significance across equipment types, particularly in automation applications.

Key applications of telescopic guide rails can be seen in assembly lines, robotics, and material handling systems. In assembly lines, these rails enable quick and precise access to components, thereby enhancing production efficiency. Robotics applications benefit from the adjustable nature of the rails, allowing robots to extend their reach while maintaining stability. Furthermore, in the realm of material handling, telescopic guide rails facilitate the movement of heavy loads, minimizing wear and tear on equipment and ensuring safety. A report by an industry consultancy noted that the integration of telescopic guide systems can reduce operational downtime by up to 15%, proving crucial for maintaining productivity in competitive manufacturing environments.

Tips for implementing telescopic guide rails effectively include evaluating the load capacity and extending range required for your specific application to ensure you select the appropriate system. Regular maintenance of the rails is essential to prevent wear, which can lead to performance issues over time. Additionally, investing in automation technologies that work harmoniously with telescopic rails can further enhance the operational efficiency of your manufacturing processes.

| Application | Industry | Benefits | Load Capacity (kg) | Material Used |

|---|---|---|---|---|

| Automated Storage Systems | Logistics | Space-efficient, Fast access | 1000 | Steel |

| CNC Machine Tools | Manufacturing | Precision movement, Stability | 1500 | Aluminium |

| Industrial Racks | Warehousing | Durable, Adjustable height | 800 | Steel |

| Telecommunications Towers | Telecom | Extended reach, Safety | 2000 | Galvanized Steel |

| Vehicle Lifts | Automotive | Space-saving, High capacity | 1200 | Aluminium and Steel |

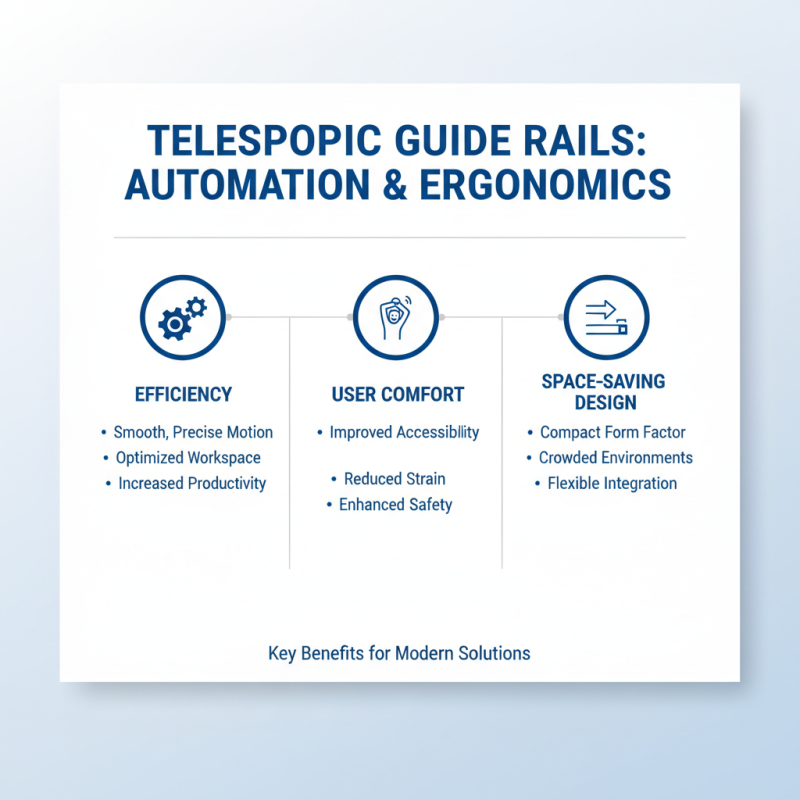

Telescopic guide rails have emerged as essential components in modern automation and ergonomic solutions, offering distinct advantages in efficiency and user comfort. These rails enable smooth and precise movement of equipment, allowing for an optimized workspace. By incorporating telescopic mechanisms, they contribute to space-saving designs, which are particularly beneficial in crowded environments. This functionality is not only vital for enhancing productivity but also plays a significant role in improving operator accessibility, ensuring safety during operations.

One of the primary benefits of using telescopic guide rails lies in the enhancement of ergonomics within the workplace. By facilitating easy access to tools and materials, these rails reduce the need for strenuous reaching or bending, which can lead to musculoskeletal injuries over time. Furthermore, their adjustable nature allows for customization based on user height or specific tasks, promoting a more comfortable working posture.

Tips: When selecting telescopic guide rails, consider the load capacity and extension length to ensure they meet your needs. Additionally, regular maintenance can prolong their lifespan and maintain smooth operation, ensuring consistent performance in your automation processes.

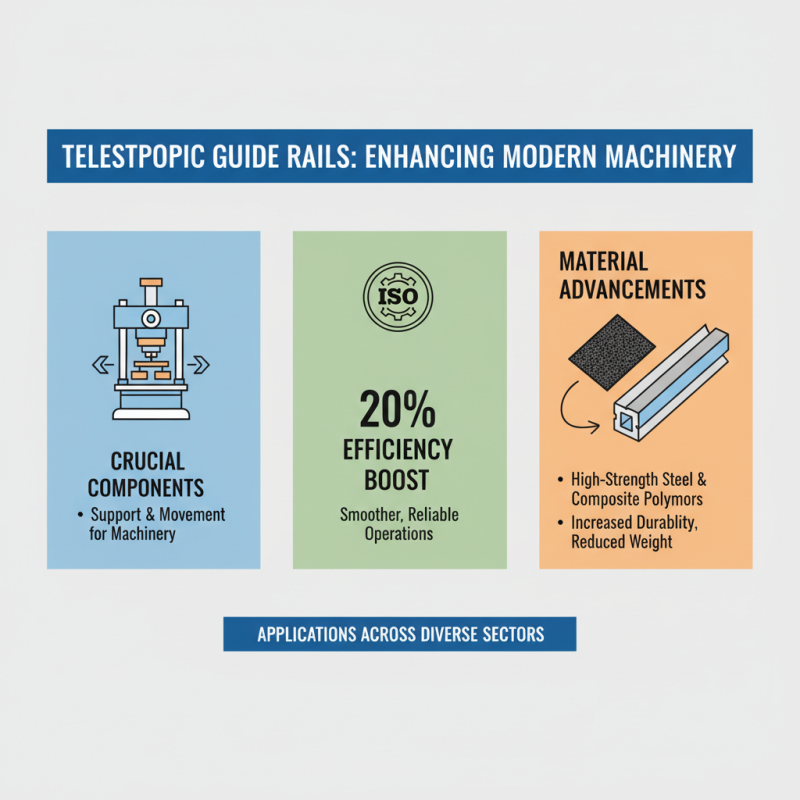

Telescopic guide rails are crucial components in various modern applications, providing the necessary support and movement for machinery and equipment. Over the years, significant advancements in this technology have led to a variety of industry standards aimed at enhancing performance and safety. According to the International Organization for Standardization (ISO), the incorporation of telescopic guide rails in industrial machinery yields a 20% improvement in efficiency by enabling smoother and more reliable operations. The evolution of materials, such as high-strength steel and composite polymers, has not only increased durability but also reduced weight, allowing for more versatile applications across different sectors.

Recent innovations have transformed telescopic guide rail technologies, with a notable trend towards automation and smart systems. The implementation of sensors and IoT technology facilitates real-time monitoring and predictive maintenance, reducing downtime and operational costs. A 2022 report by the Mechanical Engineering Society indicated that companies adopting smart telescopic guide rail systems experienced a 30% reduction in maintenance expenses. Furthermore, the ongoing research into frictionless technologies is expected to revolutionize the design and functionality of these guide rails, paving the way for their incorporation into even more sophisticated, high-performance machinery. As industries continue to evolve, the standards for telescopic guide rails will likely adapt, emphasizing efficiency, safety, and advanced engineering solutions.