Choosing the right Gliding Rail can significantly impact your project’s success. Reports indicate that nearly 70% of users experience improved workflow with the correct rail selection. However, many overlook crucial factors that play a vital role.

Industry expert John Morrison highlights, "A well-chosen Gliding Rail enhances not only efficiency but also overall satisfaction." This statement emphasizes the importance of making an informed choice. The right materials, weight capacity, and installation method can make all the difference.

Yet, people often rush the decision. They might be tempted by price alone, ignoring essential features. Understanding your specific needs is imperative. Assess your workspace carefully. Consider how frequent adjustments will be. A tailored approach not only serves the project but can lead to long-term benefits.

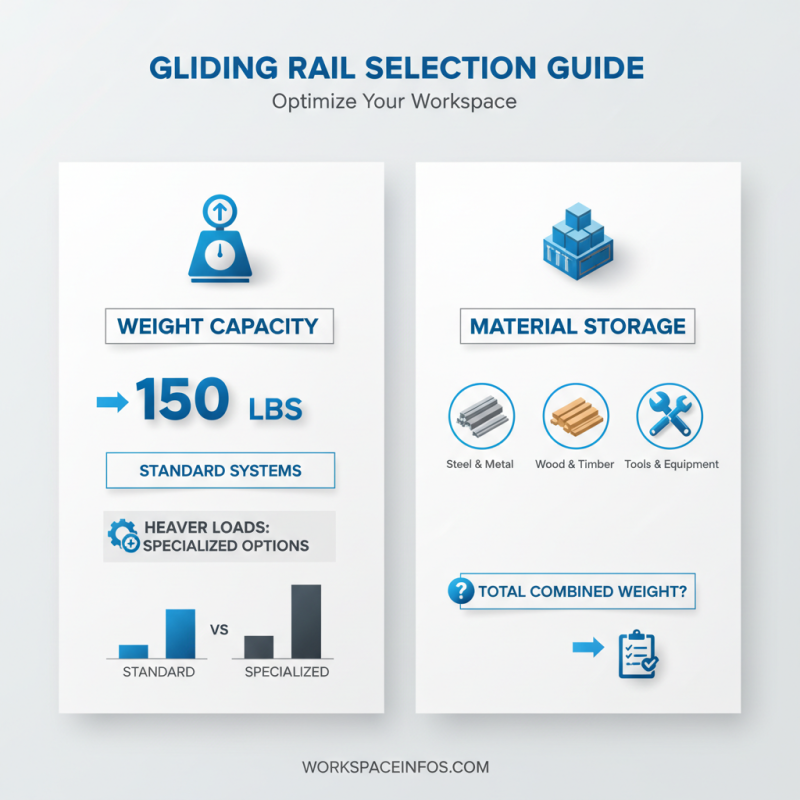

Choosing the right gliding rail for your workspace involves several factors. It's essential to consider the weight capacity. According to industry studies, many rail systems can handle up to 150 pounds. However, some heavier loads may require specialized options. Think about what materials you will store and their combined weight.

Next, consider the dimensions. A rail that doesn't fit your workspace will only cause frustration. Many reports suggest that the average desk height is around 29 inches. Ensure that the rail allows for easy access without compromising your workspace's design.

Tip: Measure your space carefully before making a choice. A slight oversight can lead to a mismatch.

Also, look for rail types that offer flexibility. Some rails allow for adjustment in length and height. This adaptability can make a significant difference in usability. It can be a bit daunting, especially for those who have fixed seating arrangements.

Tip: Consider possible future needs. What works now may not fit later.

Lastly, installation complexity can vary. Some rails come with clear instructions while others do not. Ensure to evaluate your comfort level with DIY projects. A complicated installation can lead to frustration and time loss. Always think twice before committing to a choice.

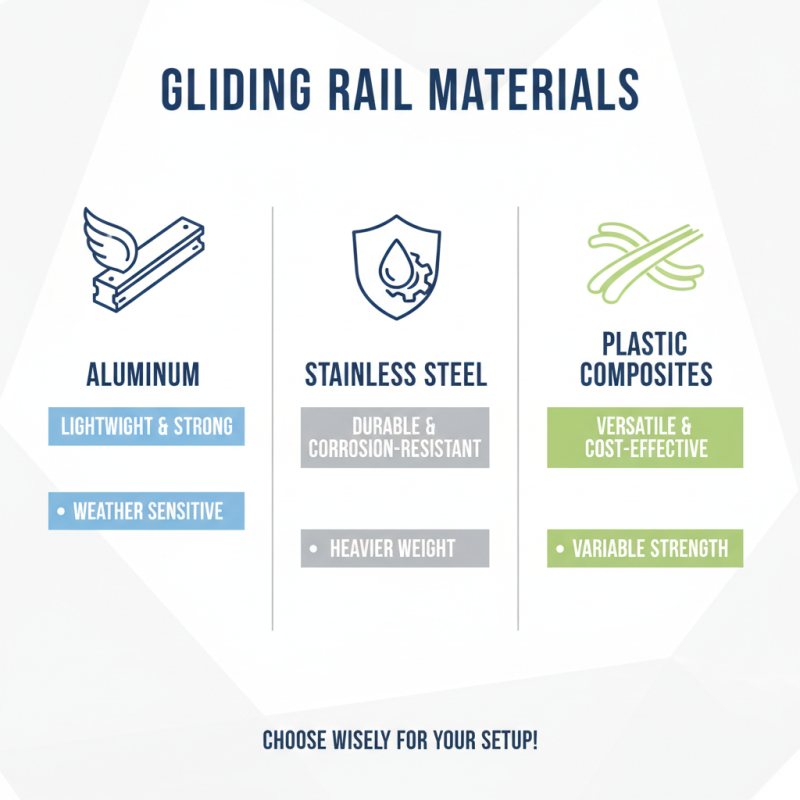

When selecting a gliding rail, understanding material types is crucial. Common materials include aluminum, stainless steel, and plastic composites. Aluminum is lightweight and strong, but it may not hold up well in harsh weather. Stainless steel is durable and resistant to corrosion, making it a popular choice. However, it's heavier, which can be a disadvantage in some setups.

Plastic composites offer a balance between weight and strength. They are often more cost-effective, yet their longevity can vary greatly. Some may degrade under UV light. Users should consider their environment. Will the rail be exposed to moisture? Is it meant for indoor use? These questions guide material selection.

Many overlook the importance of maintenance. Even the best materials need care to perform optimally. For instance, rail systems can develop issues if not cleaned regularly. Dust and debris can hinder smooth operation. Buyers often assume higher cost means better quality. Yet, even inexpensive options can work well if chosen wisely. Understanding these details can lead to better choices.

When selecting a gliding rail, understanding weight capacity is crucial. Different attachment systems can have various limits. It’s essential to know what your gliding rail will carry. If it’s for small items, a lower capacity might suffice. However, for heavier loads, ensure the rail can handle that weight efficiently.

Consider the complete setup. Sometimes, the gliding mechanism could affect weight distribution. Look for reviews or user experiences about stability. A rail that seems great on paper might not perform well with heavy items. There could be specific scenarios where it struggles under pressure.

Don't overlook the potential for underestimation. Many people assume standard capacities are enough. Yet, it’s wise to factor in unexpected weight changes over time. Not all gliding rails are built the same. Each component plays a role in overall performance. A miscalculation could lead to complications. Reflect on what you truly need for your space. Adjust your choices accordingly based on real-life usage.

When selecting gliding rails, cost-effectiveness plays a key role. You might be tempted to choose the cheapest option. However, considering long-term benefits is crucial. Some lower-priced rails may wear out quickly. This leads to additional replacement costs. A more durable option could save you money over time.

Think about your specific needs as well. Do you require heavy-duty rails or light, quick solutions? Analyze how often you'll use the gliding feature. Frequent use might justify a pricier option. Additionally, check for maintenance requirements. Some gliding rails might need more upkeep than others. This could affect your overall spending.

It's easy to overlook quality when focusing on price. But, the enjoyment and efficiency of your system depend on the right choice. Make a list of features you need. Evaluate whether the lower costs actually meet your requirements. Always weigh initial savings against potential long-term expenses. Exploring user reviews can also provide valuable insights.

When selecting gliding rails, installation and maintenance are key considerations. Many users overlook the fact that improper installation can lead to system malfunction. According to a recent industry report, 30% of gliding rail failures stem from installation errors. Therefore, understanding the specific installation requirements of your chosen rail is crucial. Some systems require precision measurements to ensure a smooth glide. Others may need special tools for proper assembly.

Maintenance cannot be ignored either. A study showed that 40% of gliding systems need repair due to lack of regular upkeep. Simple tasks such as cleaning and lubricating are essential. Failure to maintain can result in wear and tear, causing unexpected costs. Always check for alignment issues as slight misalignments can disrupt the functionality.

The materials used in gliding rails also affect both installation and longevity. For instance, some metals offer durability but may need more frequent maintenance. Conversely, lighter materials might be easier to install but could wear quicker. Balancing these factors is necessary to meet your needs accurately. The choice of gliding rails can impact not just performance but also long-term satisfaction.

| Rail Type | Material | Weight Capacity (kg) | Installation Complexity | Maintenance Frequency | Best Use Scenario |

|---|---|---|---|---|---|

| Standard Gliding Rail | Aluminum | 150 | Easy | Annually | Home Use |

| Heavy-Duty Gliding Rail | Steel | 300 | Moderate | Semi-Annually | Industrial Use |

| Compact Gliding Rail | Plastic | 75 | Easy | Every 6 Months | Office Use |

| Curved Gliding Rail | Aluminum | 120 | Complex | Annually | Creative Spaces |