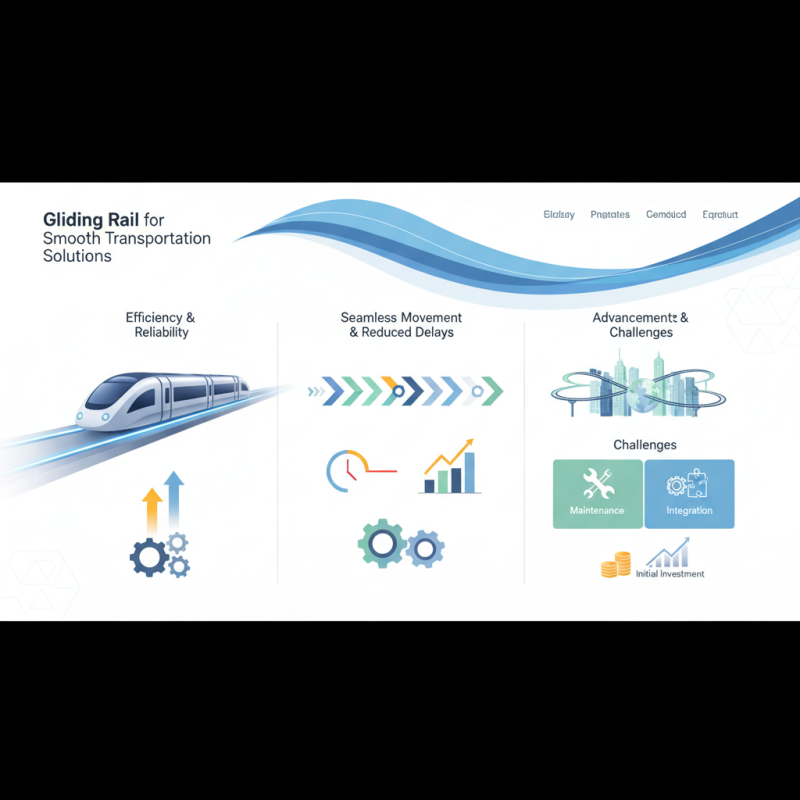

In the world of transportation, the term "Gliding Rail" is gaining attention. Experts highlight its efficiency and reliability. According to Dr. Emily Carter, a leading authority in transportation systems, "Gliding Rails offer seamless movement that transforms logistics."

This innovative transport solution is changing how industries operate. With smooth transit capabilities, Gliding Rails reduce delays and enhance productivity. The precision in their design ensures minimal friction, which is essential for rapid transport. However, the initial investment can be high, leading to some hesitation among potential users.

Despite the advantages, not every implementation is flawless. There are challenges to address, such as maintenance and integration with existing systems. Reflecting on these issues can help improve future designs and applications. Ultimately, embracing Gliding Rails can lead to significant advancements in movement and transportation efficiency.

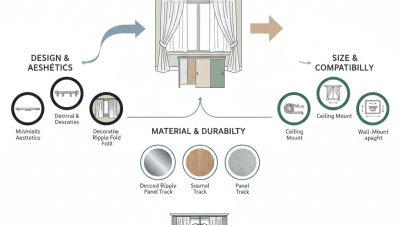

Gliding rails are an innovative solution for seamless transportation. They consist of tracks designed to minimize friction. This design allows for smooth and swift movement of various loads. Gliding rails can be used in warehouses, factories, and even outdoor settings. Their flexibility makes them adaptable to different work environments.

The functionality of gliding rails lies in their engineering. The materials used provide durability and strength. They often include rollers or bearings that contribute to the smooth operation. However, maintenance is vital. A lack of upkeep can lead to performance issues and safety risks. Regular inspections are necessary to ensure efficiency.

They offer many advantages, such as reducing strain on manual labor. Workers can transport heavy items easily. Yet, some might overlook the initial installation costs. It takes time and resources to implement. Not all organizations can afford such an investment upfront. Nevertheless, the long-term benefits often outweigh these challenges.

Gliding rail systems offer numerous advantages for transportation. They create smooth transit experiences. These systems reduce friction, allowing vehicles to move with ease. A key benefit is efficiency. Operations become faster, reducing wait times significantly.

Implementation can seem daunting. Initial costs and installation challenges may arise. However, the return on investment often outweighs these concerns. Maintenance is relatively easy. Regular checks ensure smooth functioning.

Another benefit is versatility. Gliding rails adapt to various terrains and applications. Whether in factories or urban transport, they shine. The integration can elevate systems, but planning is crucial. Thoughtful consideration of environments and needs leads to better outcomes.

Gliding rails are increasingly adopted in multiple industries for efficient transportation solutions. They provide a smooth surface for various types of loads, minimizing friction. This feature enables easy movement of heavy materials in warehouses or factories. Many facilities use gliding rails to move products from one station to another. This reduces worker fatigue and improves productivity.

In the healthcare sector, gliding rails are essential in hospital equipment transport. Stretchers glide smoothly from one area to another, ensuring patient safety. However, occasional maintenance is necessary to keep them operating optimally. Manufacturing plants also benefit from these rails, as assembly lines rely on quick transportation of components.

Transportation isn’t without challenges. Gliding rails can require careful alignment to function properly. Misalignment can lead to delays and additional costs. In aviation, baggage handling systems utilize gliding rails for efficient luggage transport. Still, issues can arise when the system gets jammed. Continuous improvement in design and application of gliding rails is important for maximizing their benefits.

Gliding rails offer significant advantages over traditional transport methods. These systems create smoother movements, reducing friction. A recent industry report highlights that gliding rail systems can improve transport efficiency by up to 40%. This efficiency stems from their design, which minimizes wear and tear on both the system and goods being transported.

Comparatively, traditional transport methods often experience delays due to their reliance on rigid pathways. In contrast, gliding rails adapt more easily to various loads and surfaces. The flexibility of gliding rails contributes to a more seamless operations process. They can handle varying weights without compromising speed. However, one must consider the initial investment. Implementing these systems can be costly upfront, leading many to hesitate.

Data shows that companies using gliding rails report a 30% decrease in maintenance costs over three years. This economic benefit is crucial for decision-makers. Yet, some industries lag in adopting these innovations. Many still cling to outdated methods. It may take time for them to realize the potential gains.

When it comes to gliding rail systems, maintenance is key for safety and efficiency. Regular inspections are essential. Operators should check for wear and tear, including alignment and lubrication. Ignoring these checks could lead to significant issues. Over time, rails can accumulate dirt and debris. This buildup can compromise performance and increase the risk of accidents.

Safety considerations cannot be overlooked. Proper training for operators is vital. They need to understand the system thoroughly. Misuse can lead to injuries or equipment damage. Emergency protocols should be established, and all users must be familiar with them. It’s important to document incidents to improve future safety measures.

Moreover, budget constraints often limit maintenance resources. This can lead to shortcuts that endanger users. Finding the right balance between cost and thorough upkeep is crucial. Regular audits can help identify areas for improvement. A well-maintained gliding rail system promotes smooth transportation while minimizing risk. However, constant vigilance and a proactive approach are necessary for long-term safety and functionality.

| Benefit | Description | Maintenance Considerations | Safety Measures |

|---|---|---|---|

| Increased Efficiency | Gliding rail systems allow for faster and smoother transportation of goods. | Regular inspections and lubrication are essential for optimal performance. | Implement safety protocols to prevent accidents during operation. |

| Space Optimization | Maximizes the usage of space in warehouses and production areas. | Ensure clear pathways and accessibility for maintenance work. | Provide training to employees on safe handling and operation of the system. |

| Versatility | Compatible with various types of transported materials. | Regular calibration may be needed to accommodate different loads. | Use proper protective equipment when interacting with heavy loads. |

| Cost-Effectiveness | Reduces labor costs and increases productivity. | Routine maintenance is necessary to prevent costly repairs. | Establish emergency procedures in case of system failure. |

| Reduced Wear and Tear | Minimizes damage to products during transport. | Focus on keeping the rail system clean and free from debris. | Inspect safety features regularly to ensure proper function. |